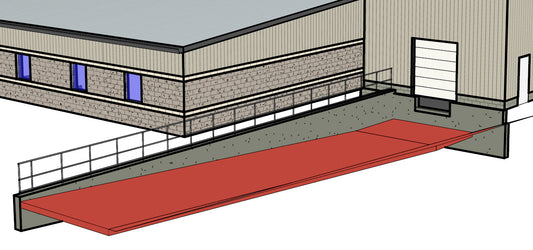

Over the years of working in the warehouse equipment industry, I have surveyed many loading docks. Loading docks are generally designed by the architect when a building is drafted and built.

There are many factors that play into a loading dock design. Such factors are the types of trailers, the moving equipment, product, environment, and industry among others.

Geometry plays a large role in the design of a loading dock and the driveway. It is simple, however often gets overlooked.

We will discuss the basics of a loading dock driveway covering common sets of factors involved in its' design. This involves a standard 53' over-the-road semi trailer, common warehouse product and equipment (fork truck), in an ambient climate.

Driveway Slope

Dock driveways are sloped to allow a semi truck to reverse to floor height from ground level. The standard trailer bed height is 48-52". Thus, the standard dock height is 48". One common misconception with this is that the dock height must be 48"+, regardless of the other factors at play. This includes where the driver has their rear axle wheels (moved forward or back) in relation to a drain, if present, which changes the bed height at rest against the dock.

For this reason, we say the drain, if present, must be within 36" of the building wall. Then the rear axle will always be in front of the drain, regardless of placement on the trailer. This will cause all bed heights be unaffected by axle placement when a drain is present.

This being considered, we can now talk about dock height. The height of the dock should be 48", EFFECTIVELY.

The other factors to consider are the building floor elevation compared to the driveway elevation at 60' out from the wall. We have 60' for the OTR semi to maneuver and reverse to the loading dock. At this top-of-ramp elevation, we can determine the driveway slope. If we want the bed height (assume 48") to meet the floor height, we need to find out the floor elevation and top-of-ramp driveway elevation. This difference, above or below floor, is added to the target dock height (48") and divided by the driveway length (60'/720") to get its' slope (rise / run).

This gives you an EFFECTIVE dock height of 48".

To measure the ACTUAL dock height, you need to work backwards to get the drain elevation (if present) and then the dock height at the wall.

To do this, take the target height of 48" and, using geometry, take the distance of the drain from the building, multiplied by the driveway slope (as a decimal, i.e. 0.048 which is 4.8%) and subtract this answer from the target dock height of 48" to determine the drain below finished floor. From there, add 1" incline to the wall for water movement to have your ACTUAL dock height at the wall.

Geometry plays a role in actual vs effective dock heights and floor lineups. This must be considered when laying out a dock driveway.

Dock Wall Offset

If there is a declining driveway to the dock, trucks will come in closer to the wall at their tops than at the bed. This must be accounted for when laying out a loading dock. At a dock with a dock leveler pit, this is considered a cantilevered pit in some instances. The minimum distance from the truck top to the wall is 4", and recommended is 6".

Loading docks are equipped with dock bumpers for a truck to rest against when parked. Dock bumpers also keep trucks out away from the wall. This is accounted for and assumed present to calculate an additional wall offset. Meaning, the wall offset is independent of the bumpers used. By calculating the offset, a standard 4.5" dock bumper can be used combined with the offset to achieve the recommended 6" gap minimum.

The standard thickness of a bumper is 4.5". When a dock is designed wrong, or for other equipment purposes, thicker bumpers are used. Other thicknesses are 6" up to 12". With a standard bumper and proper offset, you will achieve the 6" recommended minimum gap at the dock for truck access.

To determine a wall offset or building ledge to keep the trucks away, there a several factors.

Wall construction matters. If a partial wall of masonry is used at the base and metal is used part of the way up the wall or opening, this must be taken into account. For example, a 1.5" thick corrugated metal panel can add 1.5" to the offset, as it is on top of the wall if is the case for your design. Simply add the 1.5" to the already calculated wall offset for a partial building wall of metal and masonry or any projection from the wall that may interfere with truck access. Below, that would give us a new wall offset of 8.3" ~9" (because the cost is minimal to add to the projection once you're going).

The highest legal truck on US roads is 162". Our target dock height is 48" (think: bed height). And our driveway slope for this example is 4.8%. Wall offset is determined by subtracting our dock height from the highest truck, multiplying by the slope and adding a safety margin of 2". The calculation is 162" - 48" = 114" * .048 = 5.47" + 2" = 7.47" ~8". This, combined with a standard 4.5" thick bumper will provide the adequate gap at the top.

These factors are often overlooked in the design of a loading dock layout. They can be corrected after the fact, and should be corrected the first time.