The loading dock is the area of a facility that product flows in and out of on a regular basis. This movement of goods requires many pieces of equipment, and with each piece of equipment is maintenance and upkeep. Common to a typical loading dock are dock bumpers, a dock leveler or plate, trailer restraint, dock seal, and overhead door. Each of these equipment requires routine maintenance to keep proper operation, employee comfort and most of all, safety.

We recommend reaching out to your local loading dock equipment repair company for performing routine maintenance and repairs for your equipment. And as always, check with your equipment Owner’s Manual for proper operation and safety procedures when working with any equipment.

Loading Dock Bumpers

Loading dock bumpers are the first point of contact of a semi-truck and a building. They receive impact from the driver reversing against your loading dock and for this receive much wear and tear. It is important to have dock bumpers in good condition to protect your building wall from damage. Rubber dock bumpers and steel faced loading dock bumpers are both common, however steel faced are designed for heavy traffic. They are constructed of recycled tire rubber. Check to make sure your bumpers are secure and not worn out for the best protection.

Dock bumpers should not be worn down to their steel angles. Bumpers that are need to be replaced.

Door Springs or Sections

Door springs are under constant use and stress due to their nature of balancing the weight of your door to make it easy to go up and down. Door springs often break and require replacement. Along with door springs are door sections. They can take a beating during the rustle of the day moving product in and out of trucks, and often need replaced.

Dock Leveler Springs and Hold-Downs

Dock leveler springs and hold-downs are a common replacement on a dock leveler. If you have a manual activated dock leveler that won’t activate or stay down, it is most often a broken lifting spring or hold-down assembly that needs replaced. They are brand specific and sensitive to adjustment. Consult your local trusted loading dock repair company for repair or replacement of loading dock components.

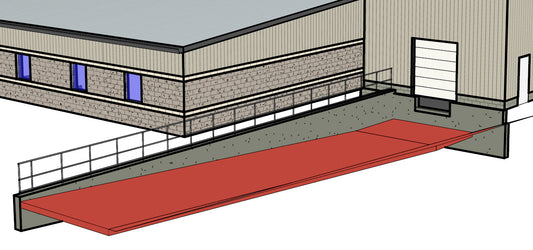

Concrete Loading Dock Repair

In time, concrete loading dock repair is necessary at your facility. Loading docks with dock levelers have a pit that each leveler sits in. Over time, the pit can deteriorate. If equipped with steel side walls, the steel is subject to corrosion. Common repairs here are capping the pit corners where the dock bumper installs to ensure solid contact with a truck.

A dock leveler also welds to the rear pit curb angle and is subject to normal wear. Problems arise from curb steel that has lost anchoring within the floor and can be a safety hazard for those using the dock. Regularly inspect your curb steel and perform building repairs as soon as any issues arise.

There are many moving components to making a loading dock operate and safe for your workers. Make sure to follow manufacture recommendations and guidelines for caring for equipment, including maintaining and repairing your loading dock equipment.